Knitting

By listening to feedback from the market, Cortland Biomedical has acquired and installed the latest in warp knitting technology and is prepared to design the next generation of knitted biomedical textiles.

![]()

Knitting

By listening to feedback from the market, Cortland Biomedical has acquired and installed the latest in warp knitting technology and is prepared to design the next generation of knitted biomedical textiles.

![]()

Biomedical Knitting Technologies for Medical Applications

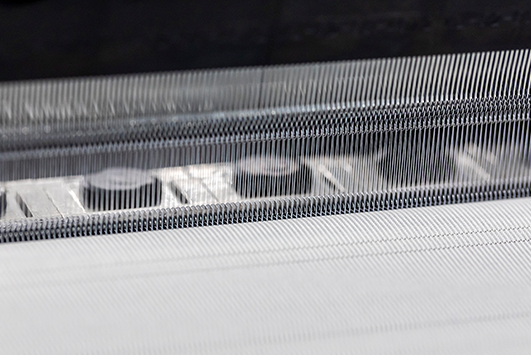

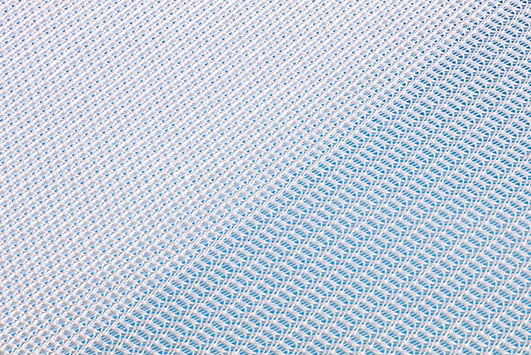

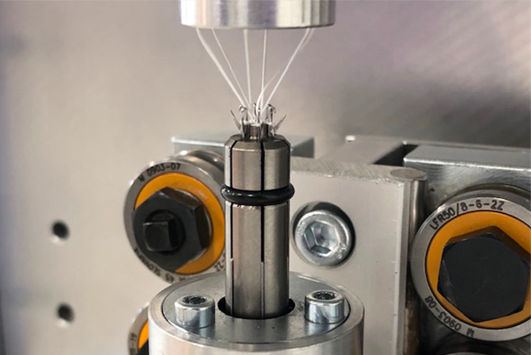

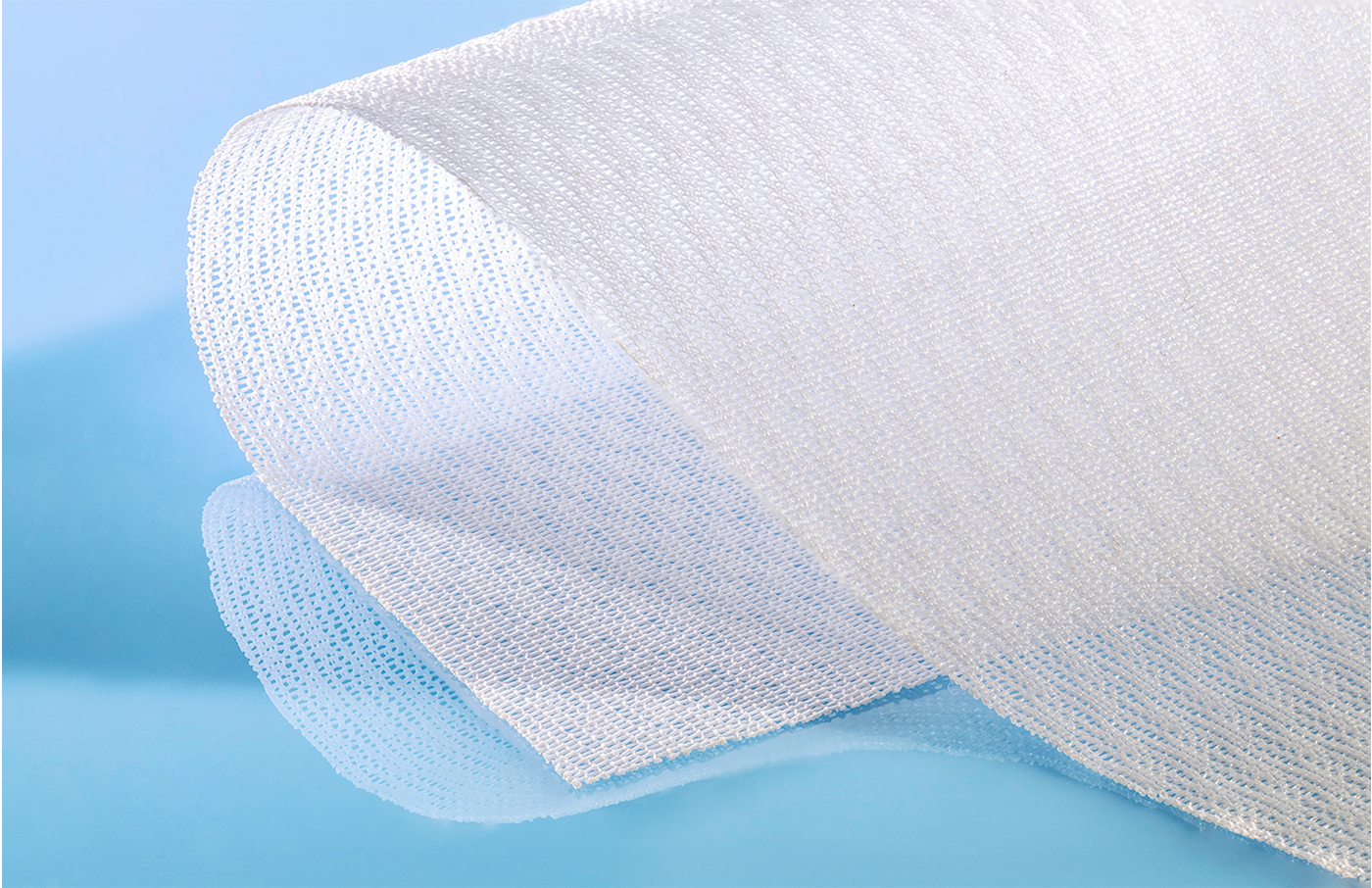

Tricot Warp Knitting

- Flat warp knit fabrics up to 130” wide

- Design capability from 1 to 4 guide bars, all electronically controlled through an on machine HMI, or remotely networked through CAD knitting software

- Servo motor controlled warp beam let-off and fabric take-up systems for precise tension control throughout the fabric formation process

- Fine gauge knitting needles for high density, low profile fabric production

- Infinite pattern repeat length to design highly engineered fabrics with regions of specialized physical and mechanical properties

- Embedded quality control features including laser stop motions to detect single yarn breaks and dropped stitch defects

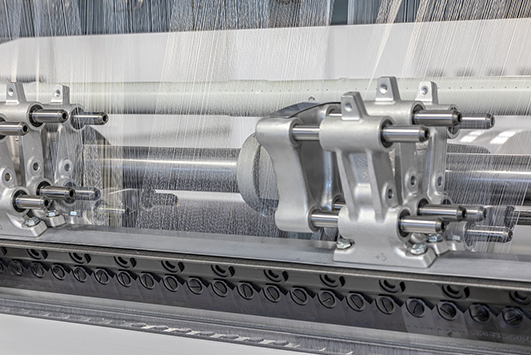

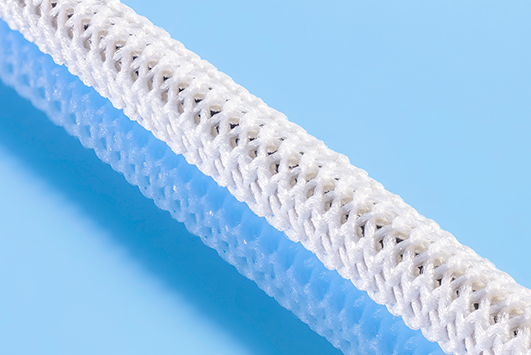

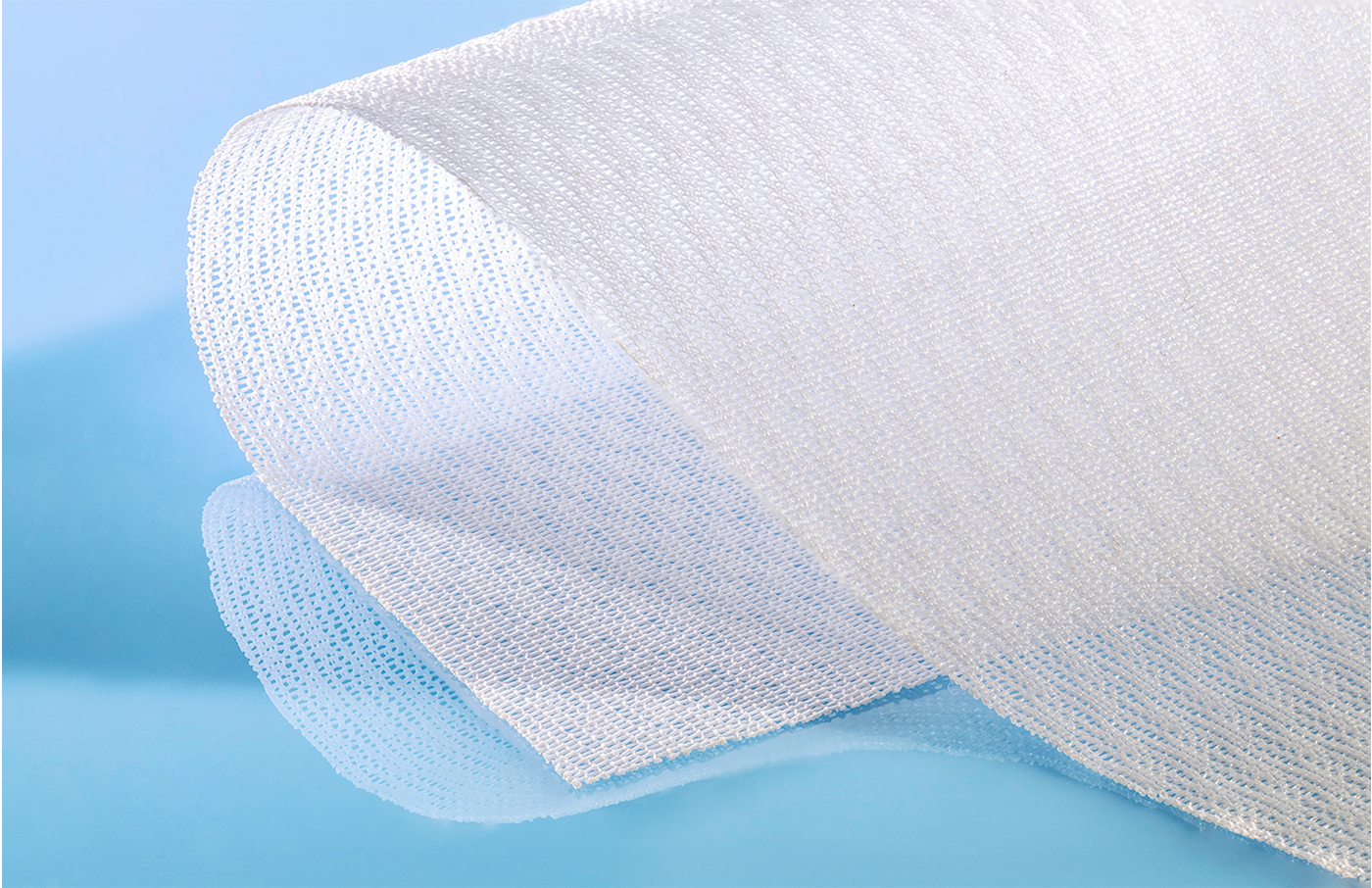

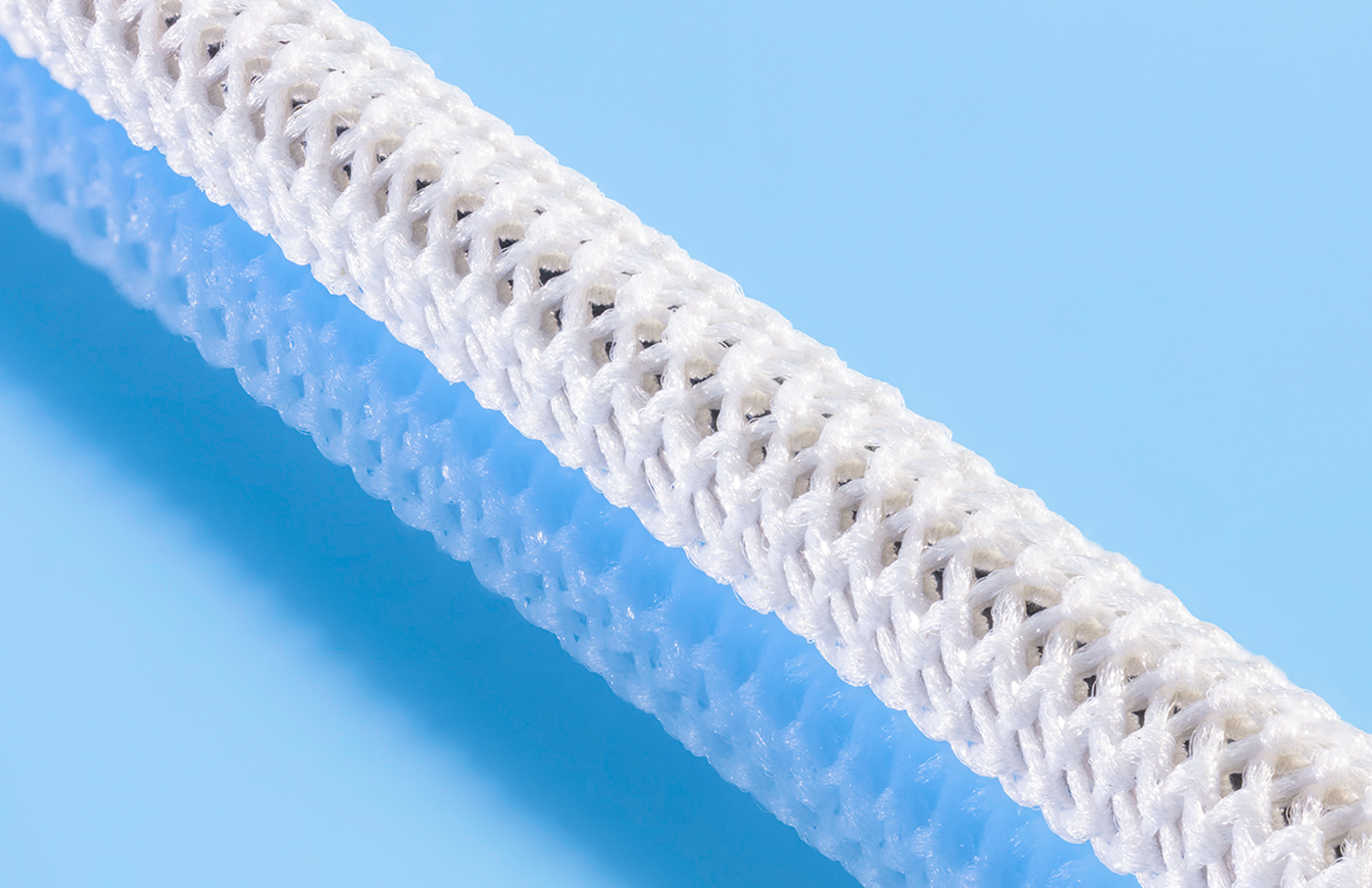

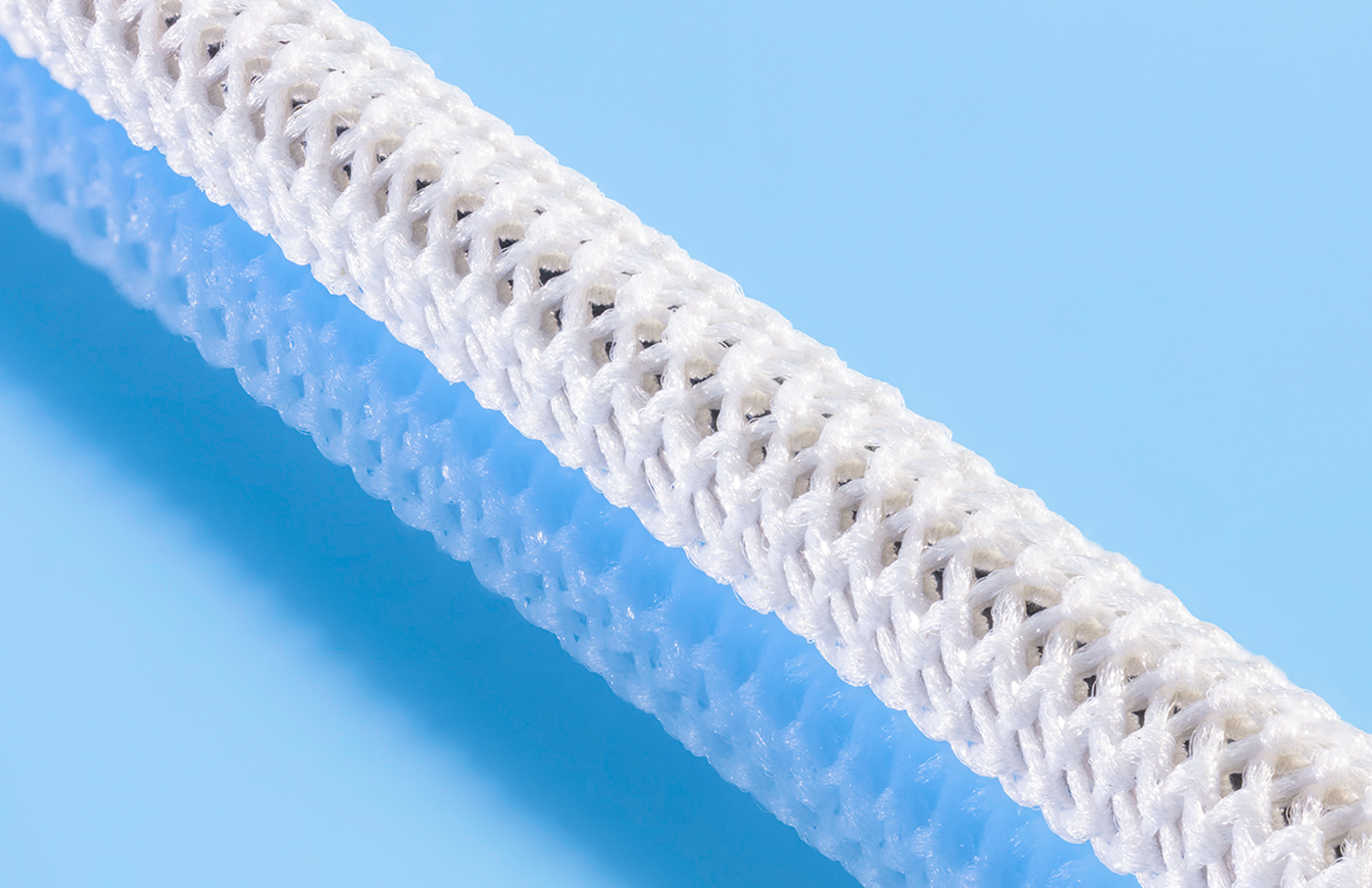

Circular Warp Knitting

- Small diameter tubular fabric offering a range of stitch configurations and densities

- Dual headed machinery to maximize production output at commercialization

- Tension controlled take-up traverse winders to deliver product to post-treatment free from distortion

- Adjacent creel with individual yarn tensioners and stop motions to ensure uniform yarn tension during the knitting cycle

- Design pattern flexibility to engineer radial compliance and axial stretch to client specifications

Types of Knitting Technology

- Tricot Warp Knitting

- Flat warp knit fabrics up to 130” wide

- Design capability from 1 to 4 guide bars, all electronically controlled through an on machine HMI, or remotely networked through CAD knitting software

- Servo motor controlled warp beam let-off and fabric take-up systems for precise tension control throughout the fabric formation process

- Fine gauge knitting needles for high density, low profile fabric production

- Infinite pattern repeat length to design highly engineered fabrics with regions of specialized physical and mechanical properties

- Embedded quality control features including laser stop motions to detect single yarn breaks and dropped stitch defects

Circular Warp Knitting

- Small diameter tubular fabric offering a range of stitch configurations and densities

- Dual headed machinery to maximize production output at commercialization

- Tension controlled take-up traverse winders to deliver product to post-treatment free from distortion

- Adjacent creel with individual yarn tensioners and stop motions to ensure uniform yarn tension during the knitting cycle

- Design pattern flexibility to engineer radial compliance and axial stretch to client specifications

Biomedical Textile Knitting Products and Technology

We offer the latest in warp knitting technology – including Tricot Warp Knitting and Circular Warp Knitting – to enable the next generation of knitted biomedical textiles.