The U.S. Navy Has a $3 Billion Annualized Rust Problem and This Newly Traded NASDAQ Company Could Tackle it Head-on with Game-Changing Technology!

Industrial Laser Equipment Leader Laser Photonics Corp. (NASDAQ: LASE) Has Just Made its NASDAQ Debut and is Seeking to Disrupt a $46B Market!

The company is pioneering a new generation of disruptive laser blasting technologies aimed at emerging and traditional markets, including corrosion control, rust removal, de-coating, welding, laser cleaning, and surface conditioning, while reducing environment hazards and increasing workplace safety!

Download Research Report

LASE is zooming in on untapped potential in massive industries including:

- Automotive

- Aerospace

- Military equipment repair

- Heavy industry

- Machine manufacturing

- Energy generation

- Nuclear maintenance and de-commissioning

- AND industries that have yet to be discovered

The company’s customer list reads like a “Who’s Who” featuring 3M, Ford, Toshiba, General Electric, Sony, Johnson & Johnson, NASA’s Astrophysics Science Division, and many more!

For over 35 years, Laser Photonics Corp. (NASDAQ: LASE) has been an innovative technology leader in the engineering and manufacturing of world-class Fiber and CO2 Laser material processing equipment for Fortune 500 and 1000 companies in various industries and is NOW A PUBLICLY TRADED COMPANY!

This is a Growth Story at the Beginning Stages!

Introducing:

Laser Photonics Corp. (NASDAQ: LASE) is the leading industrial Brand in high-tech laser systems for laser marking, laser cutting, laser engraving, and other material processing applications.

The company puts its efforts into designing equipment to the highest quality standards with full manufacturing around the world and believes in providing the best products overall with respect to quality, performance, range, and price.

"Laser Photonics currently dates back nearly 40 years and has been historically associated with high-quality manufacturing equipment for laser material processing. The Laser Photonics brand also represents a leadership position in our industry by pursuing the following key elements of our growth strategy: multi-market and multi-product approach, ascend on developing standard systems for specific markets, broaden customer relationships and new product development."

- CEO Wayne Tupuola

10 REASONS TO HAVE LASE ON YOUR RADAR:

- Laser Photonics (NASDAQ: LASE) only recently priced its IPO of 3M common shares at $5 apiece to raise gross proceeds of $15M. The stock began to trade on September 30th. This is a new situation unfolding on Wall Street and an opportunity to have the company on your radar at an early stage!

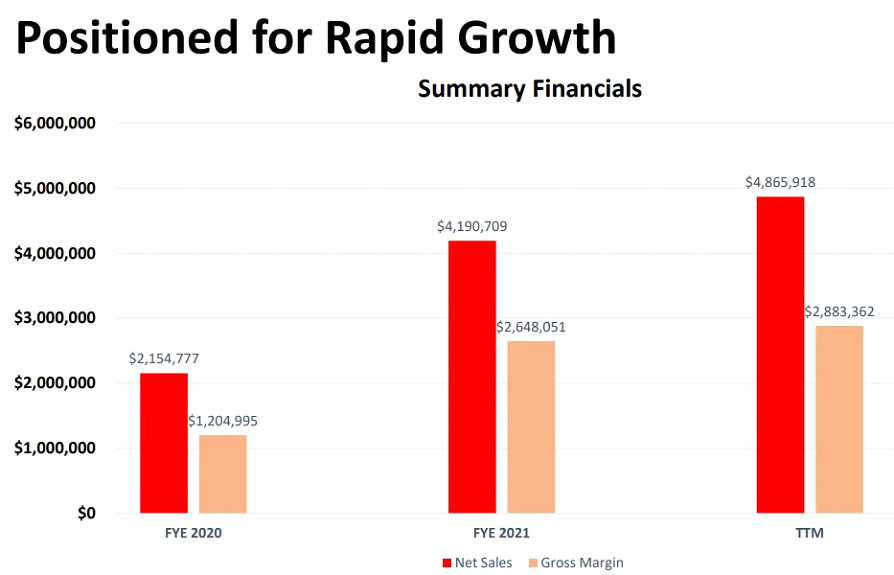

- Already PROFITABLE and with GROWTH potential, the company has been recognized as an industry leader of industrial grade laser equipment and offers the largest product line of standard and specialized laser-based systems!

- The Laser Photonics Brand of products is associated with several worldwide licenses and patents for innovative and ‘unique to the industry’ laser products and technologies.

- Systems are currently and historically used by manufacturers in the automotive, aerospace, industrial, defense, electronic, semiconductor, flat panel, and medical industries around the world.

- Customers include world-known brands such as Sony, NIKE, 3M, Delphi, NNSY-Norfolk Naval Shipyard, NASA, Cannon Air Force Base, Eaton Aerospace, GE, Caterpillar, Harley Davidson, PPG, Eli Lilly, Smith and Nephew, Millipore, DuPont, Bosch, Gables Engineering, Champion Aerospace, Smith Aerospace, Metaldyne, Dupont and Heraeus.

- In 2008 the company was nominated as the Best Brand of the Year by IEN and won several awards and recognition worldwide.

- The laser technology market size is expected to grow from USD 16.7 billion in 2022 to USD 25.6 billion by 2027; it is expected to grow at a CAGR of 8.9% from 2022 to 2027.

- In the first half of 2022, the company generated revenue of $2.56 million. That’s up more than 35% vs. the first half of 2021! The company also has a clear plan for continued growth.

- CEO Wayne Tutuola brings to the company experience based on 15 successful years of C-level management capacity in manufacturing operations, and more than 24 years of hands-on experience in the semiconductor, aerospace, food & beverage and commercial industries, including: Sumitomo Corp, the world’s second-largest wafer manufacturer in the semiconductor sector; ON Semiconductor Corp, one of the world’s largest semiconductor component companies; and Thermo-Electron, one of the world’s leading analytical instruments, lab equipment, and industrial equipment manufacturers!

- The company’s offering is being described as the “Right Place, Right Time, and Right Technology”!

The Company

Laser Photonics Corp. (NASDAQL LASE) is a vertically-integrated manufacturer and R&D Center of Excellence for industrial laser technologies and systems.

The company seeks to disrupt the $46 billion, centuries old, sand and abrasives blasting markets, by focusing on surface cleaning, rust removal, corrosion control, de-painting and other laser-based industrial applications.

LASE’s new generation of leading-edge laser blasting technologies and equipment also addresses the numerous health, safety, environmental, and regulatory issues associated with these old methods. As a result, they had have quickly gained a reputation as an industry leader for industrial laser systems with a brand that stands for quality, technology, and product innovation.

Currently, world-renowned and Fortune 1000 manufacturers in the aerospace, automotive, defense, energy, industrial, maritime, space exploration and shipbuilding industries are using the company’s "unique-to-industry" systems.

The present license holders are committed to continuing the legendary performance of Laser Photonics Brand Equipment and providing award-winning support to its past, present, and future customers.

Laser Photonic’s brand history is associated with better throughput, higher quality, and low cost of ownership for each of their products.

LASE’s line of industrial Class 1 product laser systems are designed for safety, reliability and high throughput, with fully compliant Blasting Cabinets. They can be configured with full automation for high-volume production environments.

21 CFR 1040.10 Compliance

These are Class 1 products laser systems as designated by the FDA Center for Devices and Radiological Health (CDRH).

Each system is engineered to meet or exceed the requirements for stand-alone laser systems as defined by 21 CFR 1040.10 under the Radiation Control for Health and Safety Act of 1968.

LASE’s YOUTUBE channel has several demonstrations that show what their products can do: https://www.youtube.com/c/LaserPhotonics

Quality The manufacturing of every component and sub-assembly that is purchased is manufactured with a long-term serviceability guarantee.

Performance: Each machine comes equipped with their own software package that is tailored to LP hardware. This software encompasses a quality and image analysis for each task to ensure your jobs are executed properly. The Fiber Laser has a long-term lifespan with up to 15 yr depreciation as compared to 5 yrs with other systems. The machine will perform with consistent quality for a long period of time.

Range: Their products can perform a multitude of tasks. From laser engraving to laser marking and laser cutting, their products can perform all these applications. They also offer small laser marking OEM kits for integration into I/O automated assembly lines.

Price: The reason the company’s prices are competitive is that they have the best product structure. They are able tocan build their products at a low cost and would like to extend the savings to their customers. The new generation of laser Fiber products are fully equipped with our iSeries laser marking OEM kits which makes each laser system smaller with , has fewer parts, and virtually no maintenance. With this type of structure, they are able to sell systems for what competitors are purchasing components.

Intellectual Property Portfolio

LASE has an exclusive license agreement with ICT Investments, LLC. Under the terms of the exclusive license agreement, they have a perpetual, worldwide, exclusive license to sell Laser Photonics™ branded equipment for laser cleaning and rust removal.

Additionally, the company leverages their diversified portfolio of know-how, trademarks, trade secrets and third-party confidentiality agreements, to monetize and safeguard their intellectual property.

Many elements of their laser system manufacturing process, including their unique materials sourcing, involve proprietary know-how, technology, or data that are not covered by patents or patent applications, including technical processes, equipment designs, algorithms, and procedures.

Application Testing and Research Lab

LASE offers standard and custom laser machinery that can be stationary, portable, or incorporated into assembly lines and structures. Their machines are built in-house and use the highest quality components available in the market.

The company maintains an in-house applications laboratory for processing customer samples and assisting with process development.

Their R&D team stands ready to modify standard systems or design specialized systems as new industry challenges arise; adapting to changes in manufacturing with continuous system improvements as new, viable technologies emerge.

For cleaning applications, they provide the highest quality analysis of each and every mark using their Surface Quality Assessment™ (SQA™) software. With their SQA™ software, they have the ability to guarantee and verify the accuracy and quality of their surface treatment.

The U.S. Defense Industry Represents a Major Market

The United States government and the Department of Homeland Security have approved a variety of programs where lasers have become an essential part of the present and future applications for Direct Parts Marking, UID (Unique Identifier), and deep engraving.

This resulted from the increased worldwide nature and importance of Direct Parts Marking, UID, and deep engraving during the manufacturing process for the purposes of traceability and production flow control, inventory control and renewal, service marks, product quality validation, and long-term product liability and reliability. In the private sector, a variety of government contractors elected to use laser engraving machines to comply with strict government regulations.

LASE has introduced and delivered laser marking machines and laser engraving machines that are compatible with military standards while continuing to perfect the use and development of our laser technology.

Commercial And Defense Applications:

- Small weapon identification, UID, Bar Code, Deep Engraving for such purposes as inventory, traceability, and renewal.

- Handheld laser permanent marking on all stationary and removable items such as ships, missiles, airplanes, tanks, etc.

- Real size templates and sheet metal cutting for shipbuilding, missile, and aircraft manufacturing.

- Tool, Parts, Machine Decontamination, and Surface Preparation

Revenue is exploding!

THE BOTTOM LINE

With an established BLUE CHIP customer base, Laser Photonics (NASDAQ: LASE) could head to the forefront of the laser cleaning arena!

The Brand, for more than TWO DECADES, has been the industry standard workhorse of laser subtractive material processing for world-renowned companies.

AND…. in addition to its existing line of lasers, the company is developing a new generation of laser blasting technologies focused on disrupting the sandblasting and abrasives blasting markets.

You may want to keep an eye on the laser cleaning space and a close eye on LASE who just made its NASDAQ debut. The market, estimated to be worth $588.8 million in 2018, could be worth $723.9 million by 2023, according to Reportlinker.com.

“The growth of the laser cleaning market is because of the preference toward laser cleaning over traditional approach and the increasing demand for laser cleaning in various applications. However, high cost and lack of technical expertise are restraining the growth of the laser cleaning market.”

Some of the key manufacturers in the laser cleaning market in North America are Coherent (US), IPG Photonics Corporation (US), both trading considerably higher than emerging player LASE!

Laser Photonics Corp. (NASDAQ: LASE)

only made its NASDAQ market debut in September

This Could Be an Opportunity to NOT miss!

THIS IS A PAID ADVERTISEMENT

NO INVESTMENT ADVICE